|

|

||||

|

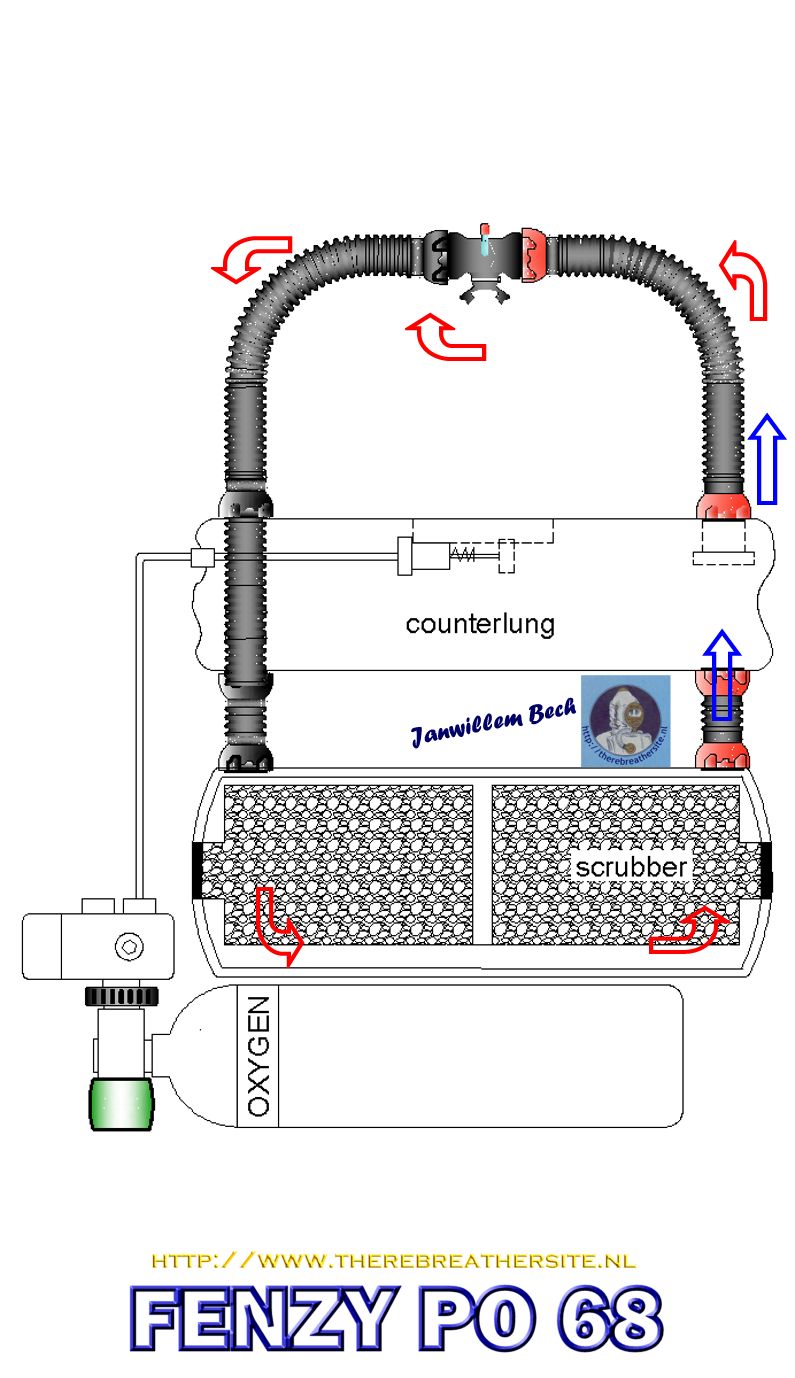

Fenzy rebreathers have always been difficult to find. Not much information can be found about these units. Now I am very pleased I managed to tear down the Fenzy PO 68. Please do not confuse P 68 with PO 68. P 68 is a passive addition trimix rebreather for depth up to 200 meters. This unit is the PO 68. Used by many military forces throughout the world. It is a pure oxygen rebreather for diving in closed circuit modus to a maximum depth of 10 meter when you are trained to be well, alive and kicking in a pO2 of 2.0 bar. Personally I would prefer to dive 6 meter maximum! I was surprised by the extreme well engineered unit that is really a jewel! Every part is beautiful shaped, well made with great attention for detail. The principle has some surprising details that can be found in this tear down. Enjoy! Janwillem Bech, 29 March 2006 |

||||

Fenzy PO 68 standing on a nice afternoon in a sunny Holland, waiting to get ripped apart ;) A characteristic feature of the PO are the 10 holes in front of the cover |

||||

When we take the bottle from the unit and turn the housing we see the scrubber and counterlung. |

||||

When the housing is removed we see the very clean design of this French combat rebreather. |

||||

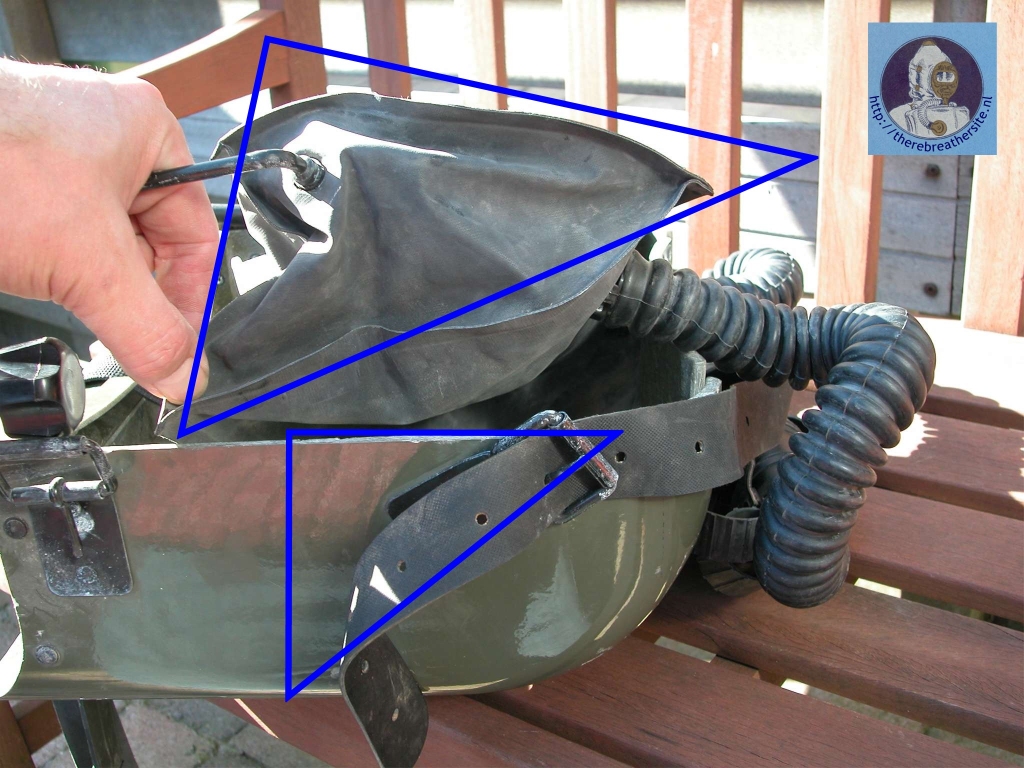

The counterlung is fixed with two very strong (POM?) connectors to the all brass scrubber. The locking system is very smart since the distance between both connectors is very tight. This results in a fitting that can not be unlocked when mounted in the housing. |

||||

This is proof of a very clever design. When you look at the buckle you see that the side is at an angle. Meaning, when you use all your force to connect the rubber strap you just need to hook up to the first corner and then pull the rest of the buckle over the angled side. Works much easier than LAR rubber straps! |

||||

Here you see the fitted bottle and scrubber with ONE strap only. Very fast and clean. The bottle also uses the oxygen feed tube to be more stable under the housing. |

||||

Here you see another very nice detail. Since the unit is chest worn, they made the scrubber and housing curved! Later you will see the superior engineering of the scrubber itself! |

||||

The very strong glasfibre housing offers space for the scrubber in such a manner that there is only very little force needed to keep it in place. Also the first glimp of the brass scrubber connectors and brass sieve. |

||||

The scrubber is filled from the side and the plugs are designed in such a manner that it can only fits the housing when the plugs closed. |

||||

The loop is permanently fixed to the counterlung. You need tools to take it off. The only text on the outside of the rebreather is "controle tested". Very secret for obvious reasons. |

||||

Here you see the fixation of the loop to the counterlung. Very solidly mounted. |

||||

Here you see a section of the counterlung matching the housing for optimal fitting! |

||||

The oxygen feed tube is connected to the counterlung and then connected with a small hose to the lung operated valve inside the counterlung. |

||||

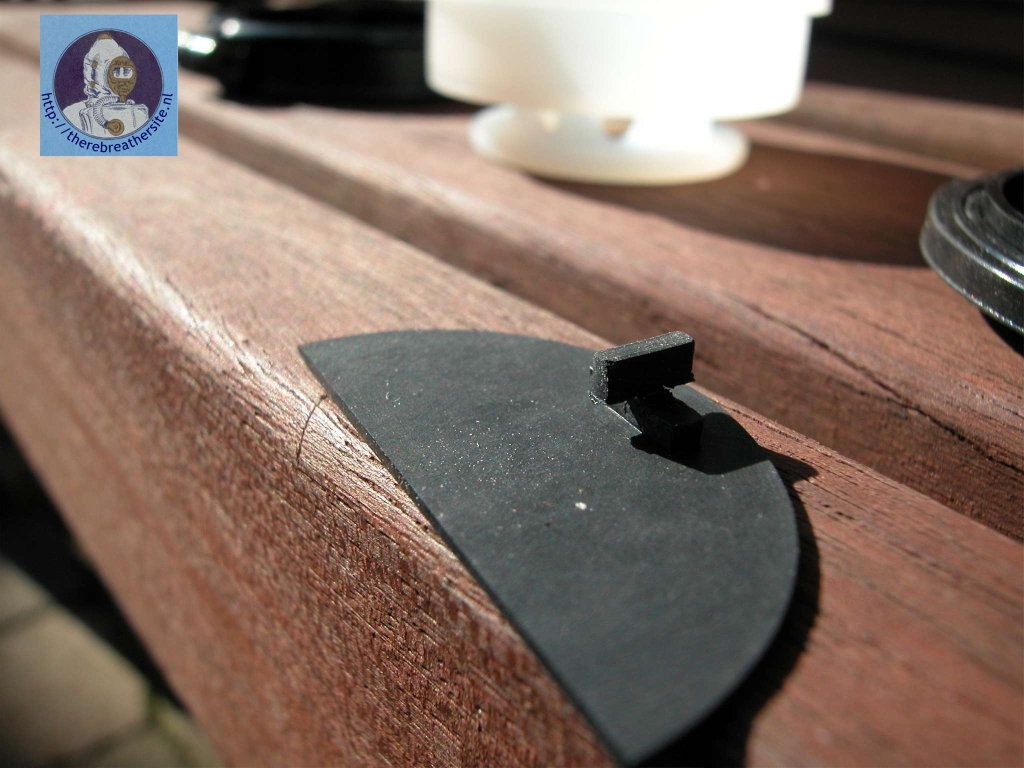

PO 68 half a circle with 8 holes and two eyes |

||||

The point where the rubber hoses enter the housing are filleted |

||||

Very simple webbing. One waist belt, one neck belt |

||||

|

||||

Solid, very versatile housing |

||||

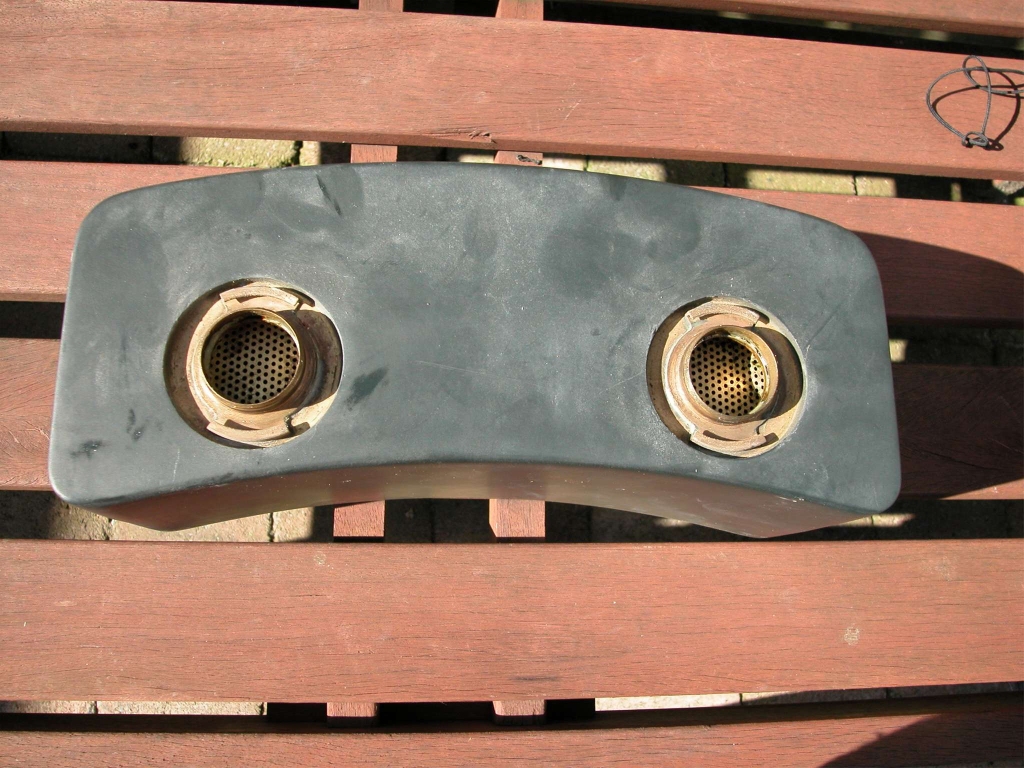

So let's take a look at the very beautiful scrubber. The completely brass unit is build in two compartments. The diagram shows the gas flow of the unit. |

||||

A rather special feature is that the exhale side of the look goes through the counterlung directly to the scrubber. |

||||

The connection with the counterlung in brass |

||||

Here you see one of the two filling points. The lever should hang down, if not the scrubber won't fit the housing. Meaning it can only be forgotten. No problem of course because the under pressure test will reveal this. |

||||

Open position |

||||

The O-ring needs to be replaced and cleaned.... |

||||

Here you see the inside of the scrubber. |

||||

|

||||

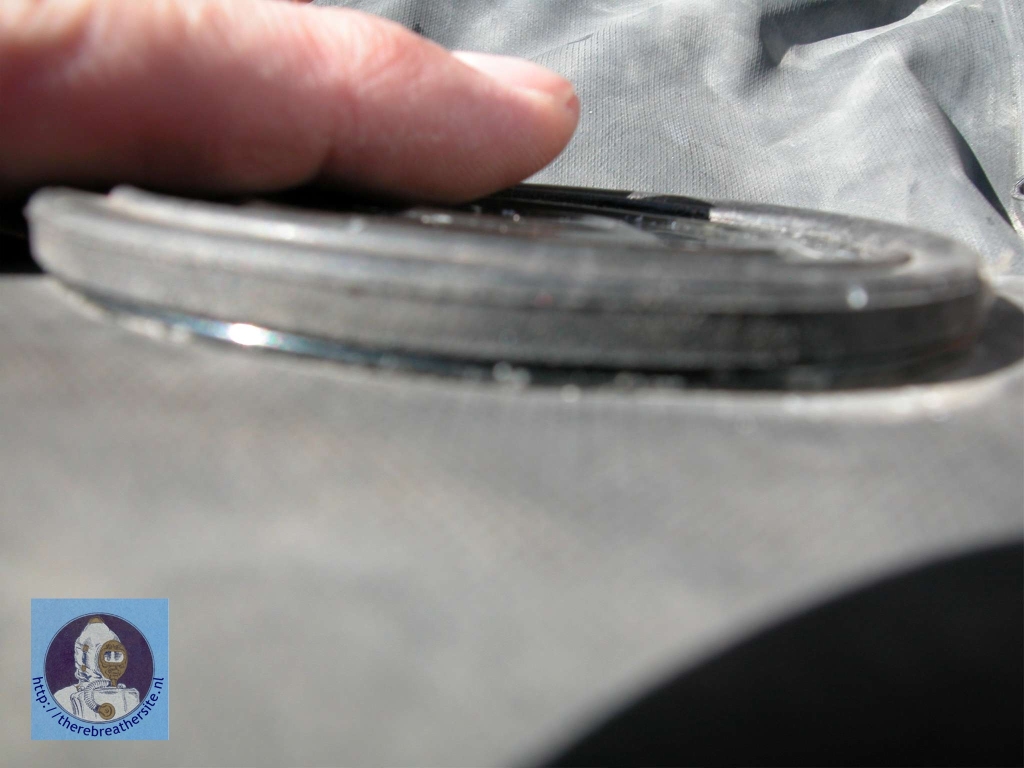

This is the cover of the lung operated valve. |

||||

The rubber seals the valve in place with a clamp |

||||

The pattern of the valve is designed in such a manner it can't slip inside the counterlung. |

||||

When we unscrew the clamp you see that even the clamp is specially made! |

||||

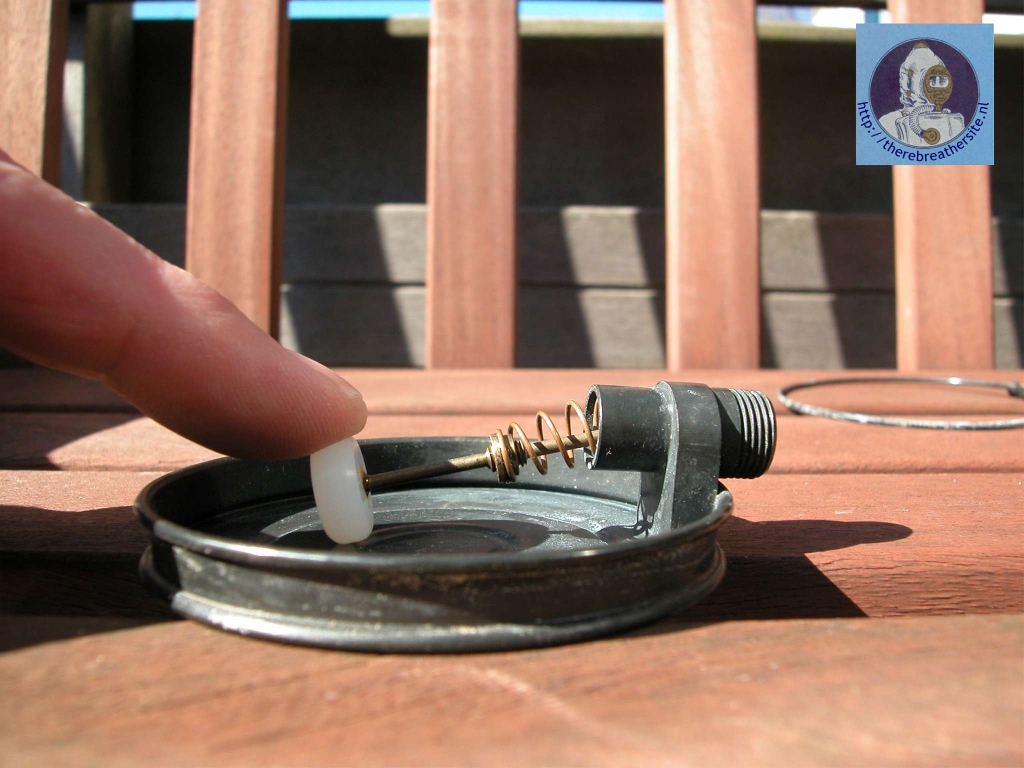

We now take out the valve cover very carefully and see the superior design of a fantastic simple valve! |

||||

Here are the detailed pictures of the CL operated valve. It can be removed without tools. |

||||

The valve is connected with a high pressure hose to the inlet point in the CL |

||||

Fixed with 1 screw ring and 1 O-ring |

||||

The profile and the metal clamp provide good fixation with the lung |

||||

The valves operates like a standard second stage regulator valve. |

||||

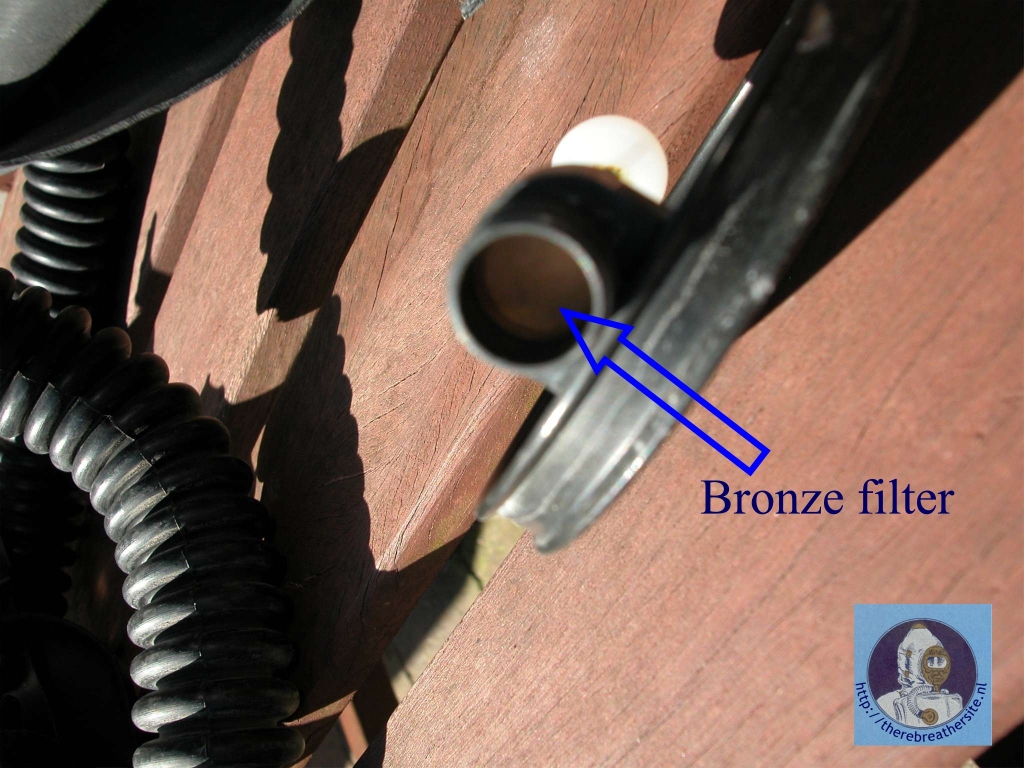

Another detail; bronze filter (the second in line) before the gas enters the valve housing |

||||

The hose is connected with Oetiker stainless steel hose clamps. |

||||

Because the flexible hose inside connects to the valve this construction is very reliable. |

||||

The valve is fitted without the aid of tools. |

||||

Another detail of the loop |

||||

Bridge type mouthpiece |

||||

The mouthpiece lever can be operated with one hand. |

||||

The rubber strap is used by the diver to prevent drowning in case of unconsciousness. It will keep the mouthpiece in the mouth of the diver! |

||||

Here you see the exhale hose entering the counterlung on the right side. The white part is the exhale valve that are situated IN the counterlung. In that way they are protected to damage and cold. The exhaled air is fed directly in the scrubber! |

||||

This is the other side of the loop. When the diver inhales he breathes from the CL through this inhale valve. This valve is also situated inside the CL! |

||||

Let us take a closer look. |

||||

The valve housing is fixed with one screw only. |

||||

You then take off the closing ring made of plastic. |

||||

The valve plate pops out and can be repaired in the field! |

||||

You need to pay attention to the flow direction! |

||||

The valve consists of two rubber parts that are fixed without tools. |

||||

Detail of the rubber valve |

||||

one valve part taken out.. |

||||

very functional. |

||||

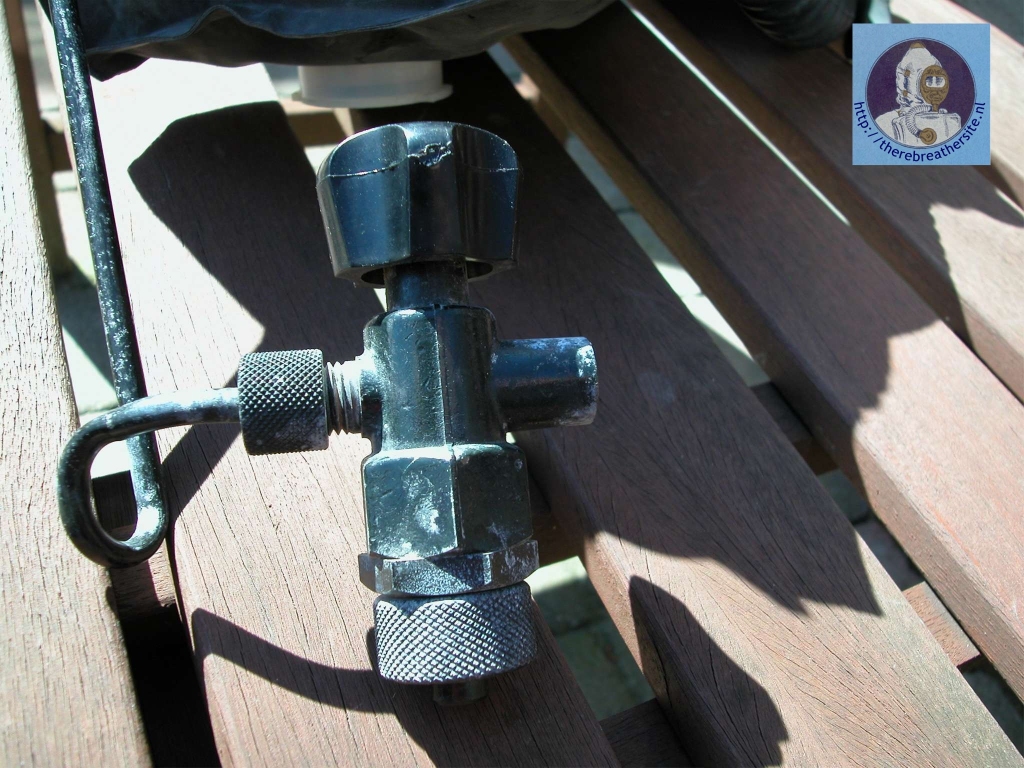

here is the complete oxygen feed line |

||||

|

||||

The valve is fitted with another bronze filter |

||||

Bottles made by S.M. Gerzat http://www.smgerzat.com |

||||

The aluminium bottle is made of 5283 alloy aluminium |

||||

|

||||

The only marking on the rebreather with the company logo |

||||

|

||||

|

||||

| I hope you enjoyed the teardown. | ||||

|

29 march 2006 |

||||

|