|

||||

|

|

||||

|

The primary goal why the Travelframe was designed is to put the entire frame and rebreatherunit into a carry-on bag to take on-board a plane. The construction of the Inspiration rebreather is very reliable and has proven its quality over the years. However, there has always been a search for an additional and more compact or universal model. For travelling the unit is not very easy to handle. One of the desires was to have a unit in which one can mount different sized bottles. To this purpose a small group of designers developed the Travelframe. Their design appeared attractive for a specific group of divers. I am very happy that I could buy one of these frames to try the functionality. Hereunder described you can find the placing of Inspiration components into the Travelframe. |

||||

|

|

||||

|

||||

| Here you see my first impression. A very

slim, light and streamlined design. The unit has been build from stainless

steel (AISI304), the joints are TIG or (WIG) welded. Very light

materials were used for this robust and strong construction. We are,

however, still awaiting the first carbon < 0.3 kg design! This unit weighs

about 2 - 2.5 kg depending the model. As you can see the scrubber easily fits in the unit. We now have to think of a way to assemble this unit further. |

||||

|

||||

| This picture, of course, can not be an example of a standard usual Inspiration rebreather. However, I am the proud owner and am using this unit since 1999! It takes courage to disassemble my baby and put it in a cold stainless steel frame..... But, I have my reasons. I am planning a trip to Italy or Egypt and I am not a millionaire. The overweight price has killed my trip to Palau, to Surinam and other locations I would have loved to go. | ||||

|

||||

| To dismantle the unit I started to disassemble the oxygen feed hose of the solenoid. | ||||

|

||||

| I then disassembled my fourth cell system. I have to tell you I really dislike this system. It never managed to give me a proper pO2 and I followed years of discussion about this subject. It is really not good. The producer of the VR3 never offered good information how to achieve a proper cell reading. I also think the new handset of APD solves all problems. Another solution would be a true 4/5 th cell core in the lid. | ||||

|

||||

| Unfasten the Velcro.. | ||||

|

||||

| Now you can unscrew the oxygen feed from the solenoid. Of course you don't need tools. It should not be too tight. That should have been told many many times during the course ;) | ||||

|

||||

| There it is. The soul of your system. There can be small differences between this picture and your Inspiration Vision electronics..... | ||||

|

||||

| Start to look like a re.... | ||||

|

||||

| I used the standard webbing to mount the scrubber. | ||||

|

||||

| OK, this is an experiment. I received a

model for a new distribution bar and tried to use it for my Travel

Inspiration (Travi or travo ;) It did not fit properly but offered me a good planning of the final bar I want to use. The red tape is put over the oxygen feed of the solenoid to prohibit contamination. |

||||

|

||||

|

||||

| I now start to dismantle the counter lungs, starting with the ADV feed. | ||||

|

||||

| Inside the unit against the back there is more Velcro to open to get access to the bolts.. | ||||

|

||||

| We then take off the wing, the lungs, the distribution bar. When you take out the DB you can see what hoses are used. | ||||

|

||||

| The wing is really simple. A tire with a center and two holes! However there is a sophisticated apparatus hanging on the wing... | ||||

|

||||

| This is the amazing story. The wings. They are constructed very very careful. Note that there are many factors which have an important role in this counter lung design, for instance the size, the materials, the dimensions, the position and many more factors. I first want to start with the original Inspiration CL to experience how they perform on this frame. Back or front mounted CL's are a next step.... | ||||

|

||||

| Wing and Counter lungs are going to be mounted on a back plate. I am searching for the best solution now..... | ||||

|

||||

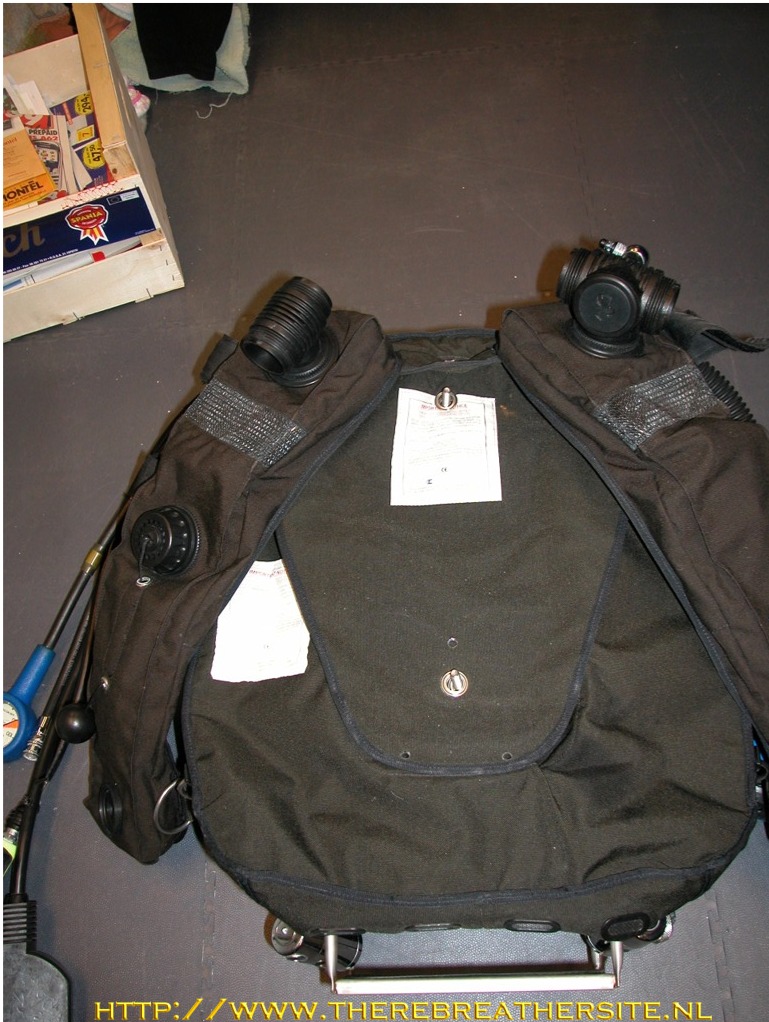

| The cover of the unit. | ||||

|

||||

|

||||

| Please do not to forget to test dive, leak test and check all parts of the unit. Ask your buddy or teacher what he thinks... | ||||

|

||||

| Here you see the final result of the rebuilding. I have changed the distribution bar and still studying the CL concept. | ||||

| During the rebuild please mark all O2 and Diluent parts. Don't think you can't make a mistake. This frame is a very nice self-study object to test your material knowledge. Also replace all O-rings and use oxygen compatible grease. The unit should be rebuilt in oxygen service for all high pressure components! | ||||

| On these links there have been a thread

about this frame. Discussion about the design process: here Feedback from existing users: here |

||||

| If you have any questions don't hesitate to ask.... | ||||

| to be continued..... | ||||

| Happy New Year ! Janwillem, en ehhhh Tino bedankt ;)) | ||||

| The Travelframe building continues here. | ||||

| OK. after finishing the nice part, now the more difficult parts appeared. The wing, the lungs, the final touch of using the frame in the right way. Some of my diving friends asked me why I changed my standard gear to the travel frame.. The weight will almost be the same... What is the advantage? I think you need to follow the next steps to find out. My first impression is that the unit compared to my (very) old unit is lighter and more flexible. I am very pleased that the unit is more easy to strap on and dives like..... ;) fantastic.. check this out | ||||

|

||||

| I decided to use stainless steel 40 mm bolds like shown | ||||

|

||||

| You need to figger out the position of the wing and CL before making the hole square | ||||

|

||||

| Mark the position to prevent damaging the frame | ||||

|

||||

| OK when shown in this resolution it is not exact square ..... ;) | ||||

|

||||

| Now the bolts won't offer any problems when mounting your wing in foreign countries.... | ||||

|

||||

| This is the position I added my bolts and wing.. | ||||

|

||||

| Here is an idea. When you have added both bolds just add a elastic to prevent the bolts from falling in the unit. Just leave the elastic during the dive.. | ||||

|

||||

| I have added some protection strip in the unit to prevent cutting when opening the valves. I have written to the manufacturers to fold this part of the frame to. I really dislike sharp edges... | ||||

|

||||

| The material weights nothing and is used in the car industry | ||||

|

||||

| I have added two metal eyes in the wing on the original position | ||||

|

||||

| The standard position of the bolts correspond the distance | ||||

|

||||

| I did the same with the original counter lungs | ||||

|

||||

| Just place them over the wing | ||||

|

||||

| Nice ehh | ||||

|

||||

|

||||

| Now, the backplate.. I found my ideal plate at Sharkeysstainless. He is from the USA and lives in Holland. Robert has a lot of experience with back plates and is always helpful picking the right model. | ||||

|

||||

| I did not choose the DIR style ;) | ||||

|

||||

| I used D-rings and the original buckles to faster the front mounted counter lungs. | ||||

|

||||

| To achieve the main purpose of the travelframe I have bought Scubapro belts to fasten the bottles. It is possible to fix a wide range of bottles with this top material. | ||||

|

||||

| To lift the unit I use two of these titanium hooks. During the dive I just take them off | ||||

|

||||

| A small D lock offers a point to hang all parts during the transport. | ||||

|

||||

| The handsets safely connected. | ||||

| Yesterday I have been diving the unit. I am

very happy to tell you that the unit dives like a dream. I just need to add

2-3 kg weigh on my belly while diving a semi closed neoprene suit. I think

this configuration is much better for me ;) I will keep you informed when

returning from the southern Egypt trip in May... Janwillem Bech 2006 |

||||

|