|

|

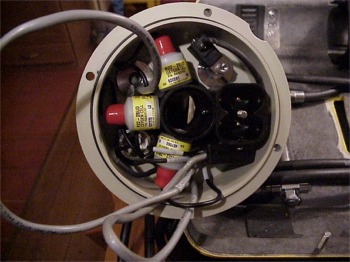

Here the inside of the scrubber lid. If you want

to know the cell numbers you could take a short look at:

cellnumbers. What we want to do is to check the cells on

closed pressure balancing holes (PBH) and to make a small 2 mm

hole in the red caps. The purpose of the holes is to be sure the

pressure is equalised on both sides of the circuit board. |

|

First of all we have to prepare the inside by

making access to the cells. I preferred to cut the Ty-rap for

maximum space. |

|

|

|

Now there is a better view in the lid. I took

out the batteries for safety reasons. When the wiring is

manipulated I think it is better to have no current. |

|

Now we need the nice standard equipment

delivered with the inspiration, to unscrew the nut on the top of

the scrubber lid. |

|

|

|

Here it is, take care that you place the tool

very tight to the ring to prevent damage. You do not need to

block the cell holder on the inside. |

| Now turn left for unlocking the ring. (CCW) |

|

|

|

Now you can gently take out the cell holder and

see the components. |

| Gently pull the red cap from the cell |

|

|

|

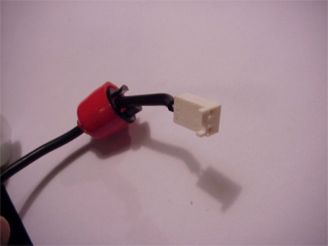

Now pull the black connector lock |

| And finally pull the white connector from the

cell |

|

|

|

Now you can unscrew the cell by tuning left (CCW) |

| Check your cell on type and serial number and

write it in your logbook. THIS is the moment to start your cell

registration! |

|

|

|

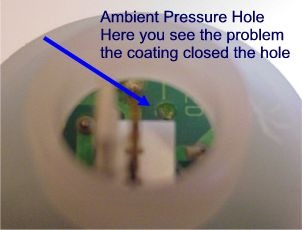

Here is the cell shown on the connector site.

The blue arrow points to the pressure hole. As you see this one

is open and fine. |

| Here you see the same cell, but on the other

site. Here you see the problem, the hole is closed with the

coating. As Martin wrote it could only cause a problem with

both holes closed, I prefer both holes opened so I decided

to arrange this. |

|

|

|

I have a very nice tool, a present from my

dentist. This tool is very capable to punch the small hole and

solve the problem. APD advised to sent the cells back when both

holes were closed, but in my case only one hole was. If both

holes are filled with the coating I would choose to sent them

back. |

| Here you see the cell with the punched hole. |

|

|

|

Now we have to make a hole in the red caps to

let the air equalize. |

| Here a warning is at his place. Take great

caution to not damage the wire to the cell. I bend the wire away

from the 2 mm drill, so if it would punch through with force, it

would not damage the isolation. |

|

|

|

That's done |

| Here you see the result. Be sure the hole is

clean and you should be able to see through. |

|

|

OK, now replace the cell and the red cap, and

repeat these steps for cell 2 and cell 3. |

| Before replacing the cell holder check the

solenoid wiring and take care that the wire is in parallel

direction of the gas addition. |

|

|

|

Here you see a detail of the inside of the

scrubber lid. Before replacing the cell holder, be sure that the

O-ring is in place. Also here is seen that the cell holder will

only fit in one way because a quadrant of the fitting is edged. |

| Now gently replace the cell holder. Let the

wiring point outside the unit. Gently turn the cell holder till

it snaps into position. Now replace the locking ring. Don't

forget the blue indicator. |

|

|

|

Finishing this check, you rearrange the cabling

and punt a new Ty-rap®. Replace the batteries and check

functionality. |